Distinguishing Between Flat Knitting Machines and Circular Knitting Machines

These machines are specifically designed for the production of fabrics like T-shirts, jersey fabric, and sportswear. Unlike flat knitting machines that move needles horizontally and vertically, circular machines use a circular needle bed to transform yarn into a continuous tubular fabric.

1. Structure

Circular Knitting Machine: Features a cylindrical arrangement of needles, allowing for continuous knitting. The fabric is created in a tubular form without seams.

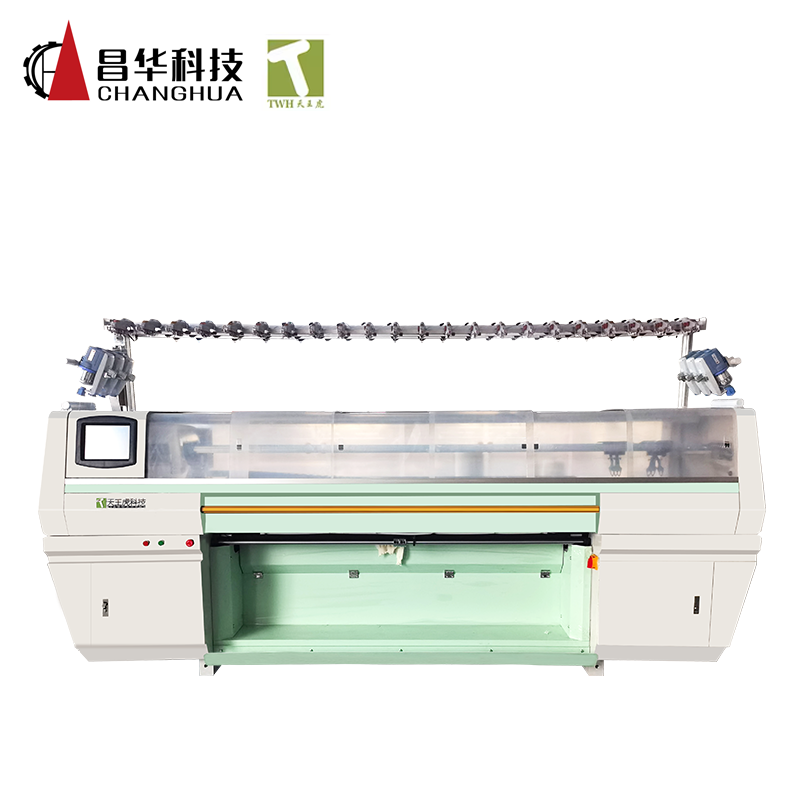

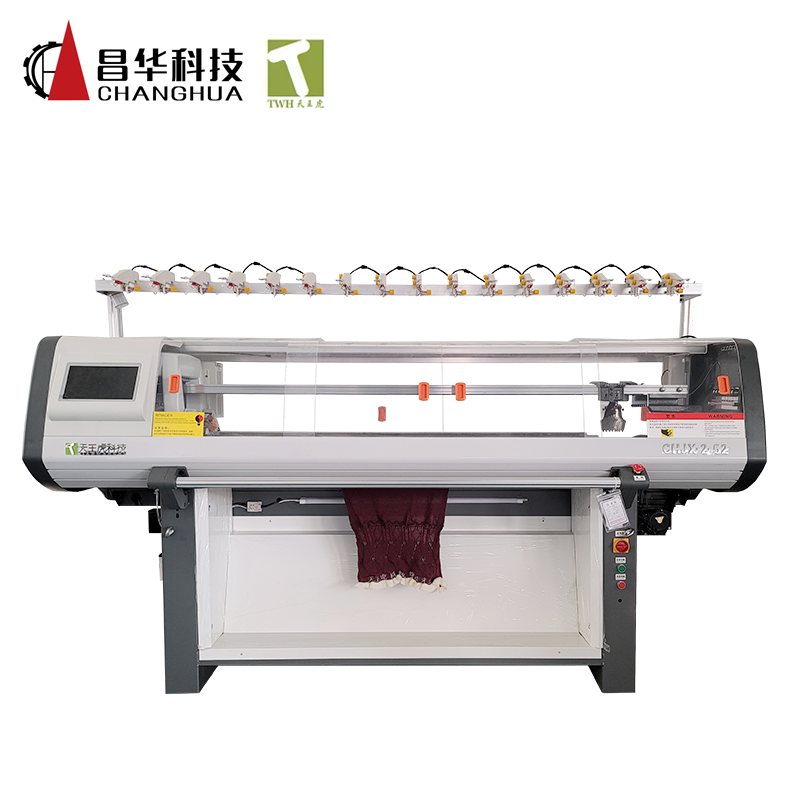

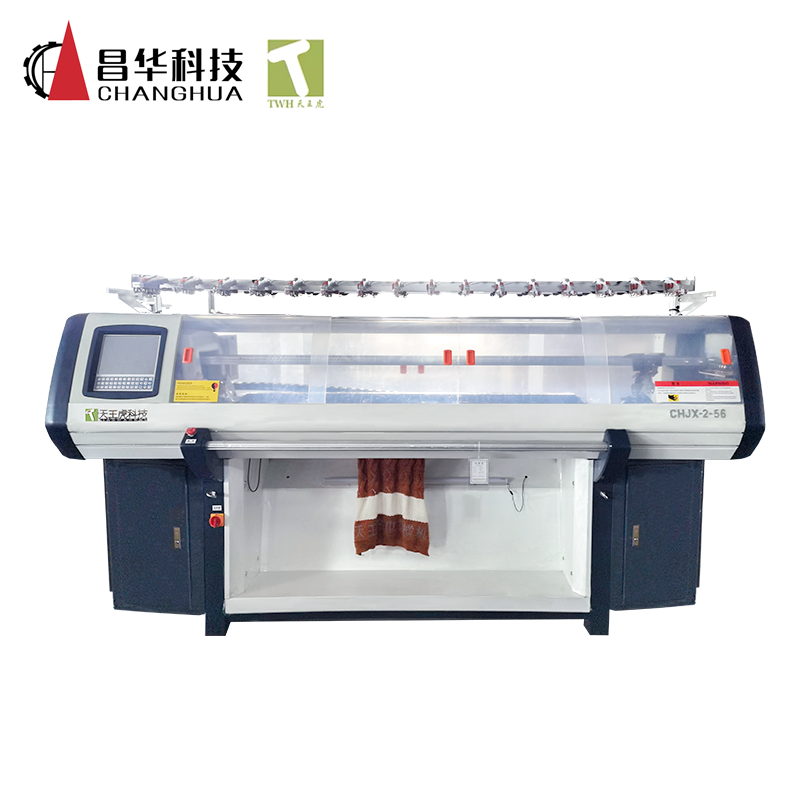

Flat Knitting Machine: Has a linear arrangement of needles that knit back and forth, producing flat pieces of fabric.

2. Fabric Type

Circular Knitting Machine: Produces seamless, tubular fabric, ideal for garments like t-shirts, leggings, and socks.

Flat Knitting Machine: Creates flat pieces of fabric, suitable for items such as sweaters, blankets, and scarves, which may need to be sewn together.

3. Applications

Circular Knitting Machine: Commonly used in high-volume production for clothing that requires less complexity.

Flat Knitting Machine: Often used for more intricate designs and patterns, allowing for customization and detailed textures.

4. Speed and Efficiency

Circular Knitting Machine: Generally faster and more efficient for mass production of seamless items.

Flat Knitting Machine: Slower for large runs but offers greater design flexibility.

5. Design Capability

Circular Knitting Machine: Limited to simpler patterns and shapes due to its construction.

Flat Knitting Machine: Capable of producing complex patterns, textures, and variations in fabric.

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

ភាសាខ្មែរ

Bahasa Melayu

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

қазақ

Српски

हिन्दी

Kiswahili

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

עברית

اردو

Shqip

বাংলা

Hrvatski

Gaeilge

Māori

සිංහල

नेपाली

Oʻzbekcha

Aymara

Azərbaycan dili

Беларуская мова

Български

guarani

Lietuvių

Runasimi

Türkmençe