If you're searching for "where to buy a knitting machine," you're likely looking for a reliable, high-quality solution to streamline your textile production or enhance your creative projects. Knitting machines have revolutionized the textile industry, offering speed, precision, and versatility for both small-scale designers and large-scale manufacturers. Among the top manufacturers in this space, Changhua Smart Manufacturing Technology Co., Ltd. stands out as a trusted name, delivering cutting-edge computerized flat knitting machines for over 20 years. In this comprehensive guide, we'll explore why Changhua is the go-to choice for knitting machines, where to buy them, and how they can elevate your production.

Why Choose a Knitting Machine?

Knitting machines have transformed the way fabrics are produced, offering unmatched efficiency compared to traditional hand-knitting methods. Whether you’re a fashion designer, a small business owner, or a large-scale textile manufacturer, a knitting machine can help you:

Increase Productivity

Automate repetitive tasks and produce high-quality fabrics in less time. Enhance Creativity: Create intricate patterns, textures, and designs that are difficult to achieve manually.

Reduce Costs

Minimize labor costs and material waste with precise, computer-controlled knitting.

Support Sustainability

Produce customized designs on-demand, reducing overproduction.

Introduction to Changhua: A Leader in Knitting Machine Manufacturing

Located in Changshu, Jiangsu—the heart of China's clothing industry—Changhua Smart Manufacturing Technology Co., Ltd. has been a pioneer in knitting machinery for over two decades. With a mission to “promote the modernization of the knitting industry through development and innovation,” Changhua has established itself as a global leader in computerized flat knitting machines, embroidery machines, and more.You can download our comprehensive PDF guide on the  Changhua flat knitting machine.pdf and

Changhua flat knitting machine.pdf and  one stop programmes.pptx to help you make an informed decision.

one stop programmes.pptx to help you make an informed decision.

Types of Knitting Machines Offered by Changhua

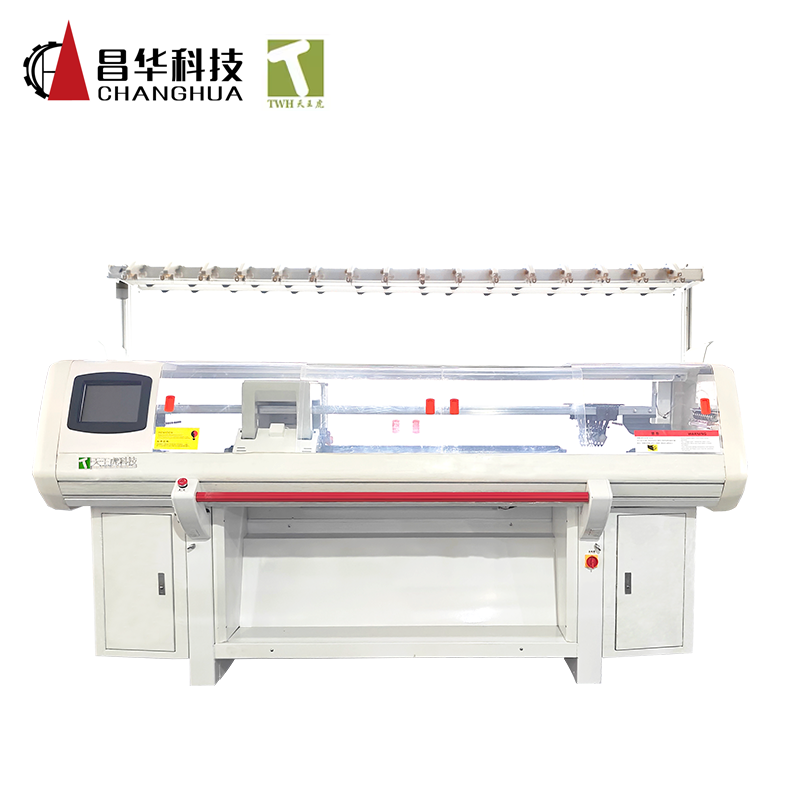

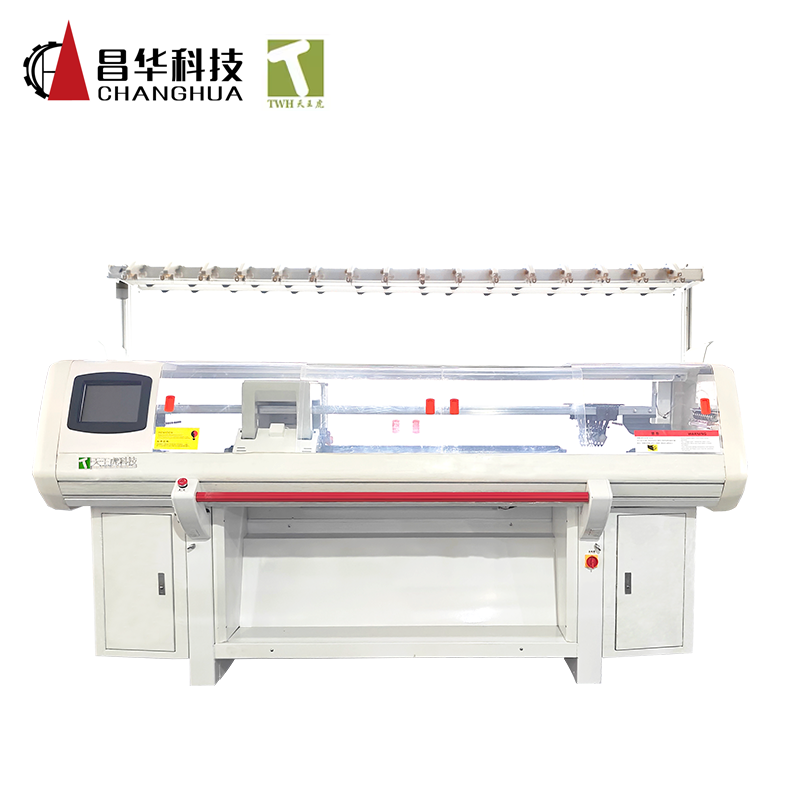

Computerized Flat Knitting Machines

These high-tech machines use computer controls to produce flat fabrics with precise patterns and textures. They are ideal for sweaters, cardigans, blankets, and accessories.

Features

Double-system functionality for high-speed production. Dynamic stitch control for intricate designs like jacquard, intarsia. Compatibility with various yarns, including wool, cashmere, cotton, and blended fibers.

Applications

Fashion garments, home textiles, and technical fabrics.

Shoe Upper Knitting Machines

Designed for creating knitted shoe uppers, these machines are popular in the footwear industry.

Features

High-speed production for large-scale manufacturing. Ability to produce lightweight, breathable fabrics. Customizable patterns for branded designs.

Applications

Sneakers, casual shoes, and athletic footwear.

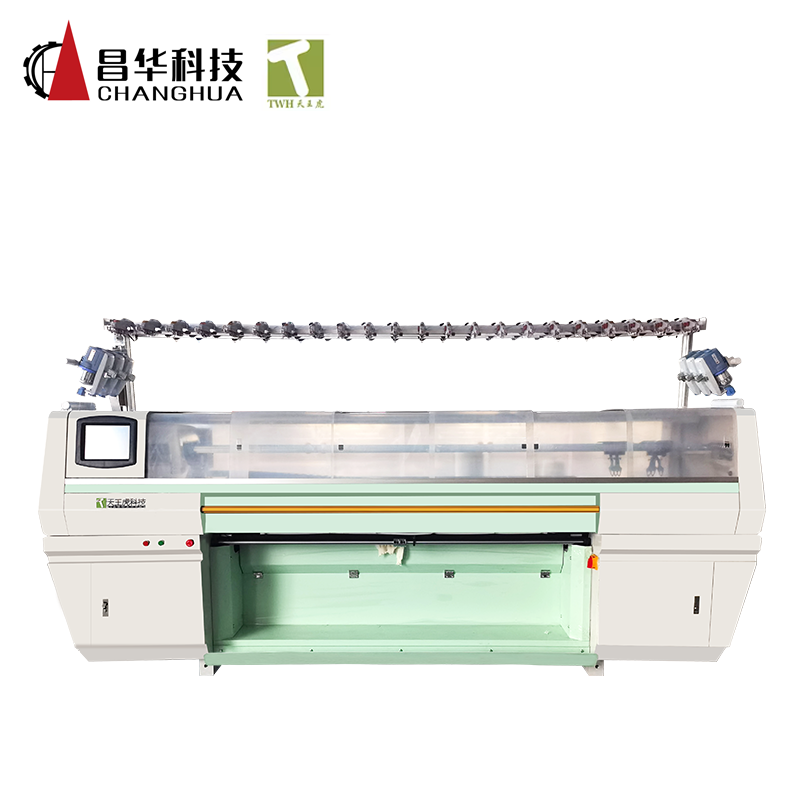

These machines produce seamless knitwear in one piece, eliminating the need for sewing. They support sustainable manufacturing and mass customization.

|

|

Gauge | 6.2G、7.2G、9.2G、10.2G、13.2G |

Knitting width | 72,80 Inch |

Knitting system | WHOLE GARMENT SYSTEM |

Knitting speed | Controlled by servo-motor with 128sections optional, max speed reach 1.6m/s. |

Knitting function | Pointelle, tuck, intarsia, needle, all kinds of jacquard, apparent shape, open needle, hidden shape and so on. |

Racking | Controlled by servo-motor racking within 2 inches and with fine adjusting function. Transfer and knit occurs synchronous, more efficient. |

Stitch density | Controlled by stepping motor, 128 section stitch select-able adjustable scope supported by subdivision technology:0-650 the stitch of the knitwear can be accurately controlled. |

Dynamic stitch | Using high speed stepping motor, multi-stitch function can be achieved in one line. |

Needle selection | Advanced encoder reading pin.8-stage selecting needle setup composed of special electromagnet is regarded as efficient full width jacquard needle selector, which can be installed or removed simply from the carriage and maintained easily. |

Transfer system | Combined design, single or double cam system all cam transfer together or separately. Also one can do transfer, another cam system for knitting, which will achieve high production. |

Quickly turning | Intelligent switching braiding system improves machine weaving efficiency. |

Take-down system | The transverse tension and front and rear bed are separately controlled. It can realize the independent control of a variety of pulling forces and front and rear beds in one line, and meet the pulling force requirements of different organizations. It is a necessary configuration for whole garment. |

Color-changing system | 2x8 yarn feeders on each side of 4 guide rails, shift able on any needle position; Motorized Feeder (Optional). |

Yarn feeder device | Accurately control the tension of the yarn and ensure the consistency of the whole woven piece quality. |

Protection system | The machine will automatically alarm if yarn-breaking, knots, floating yarn, rewind, end of knitting, fail of racking, needle breakage, error programming occur, also set up the safety auto-lock protect device. |

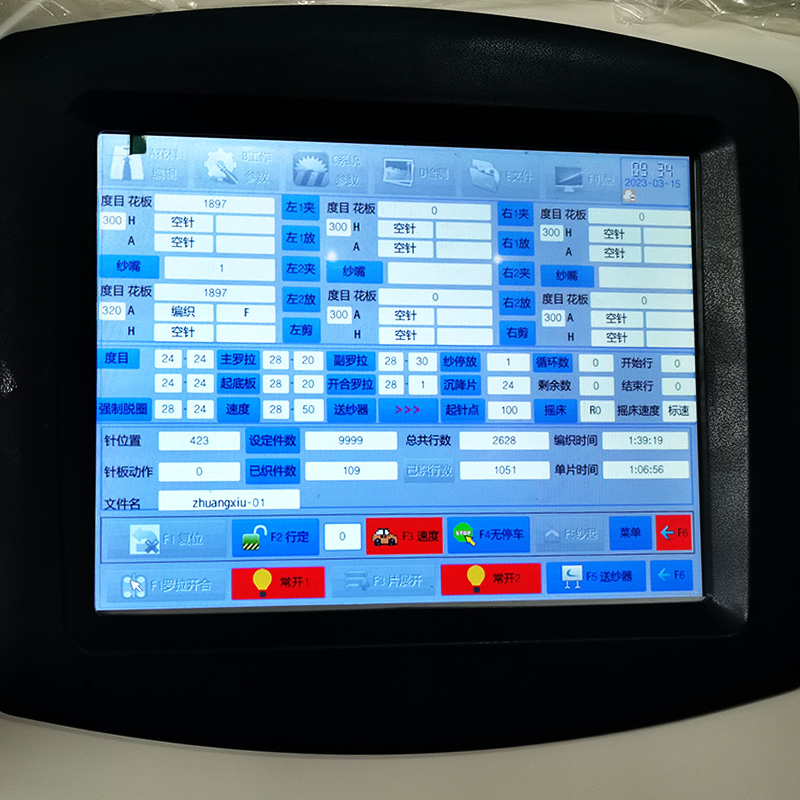

Control system | 1. LCD industrial display, can display various parameters, which can be adjustable during operation. 2.USB memory interface, System memory 2G. 3.Free design system is visual and easy to understand and software upgrade free of charge. 4.Support multi-language operation as Chinese and English, Spanish, Russian etc. |

Network function | Automatic refueling: Control the refueling time and frequency by setting the time. The oil pump lubricate the jack and long jack needle on the needle bed automatically to reduce the wear of the machine and increase its service life. |

Power supply | Single-phase 220V/three-phase 380V,adopt advanced CMOS technology, having memorizing function at power shock stop. |

Non waste yarn Comb device | The device equipped with 2 clips and 1 scissors on both sides, High precision step motor is used for wire feeding, and servo motor is used to control up and down. |

Volume and weight | 3500*1000*1800mm,1450kgs(72inch);3700*1000*1800mm,1500kgs(80inch) |

Sinker system | Controlled by stepping motor, adjustable to different knitwear, up to be various results of shaping and patterns. |

Reducing device | Automatic refueling: Control the refueling time and frequency by setting the time. The oil pump lubricate the jack and long jack needle on the needle bed automatically to reduce the wear of the machine and increase its service life.

|

Where to Buy a Changhua Knitting Machine

Directly from Changhua's Official Website

Website

https://www.changhua-knitting-machine.com/

Benefits

Access to the full range of Changhua knitting machines. Detailed product specifications and pricing. Wholesale purchasing options for bulk orders. Direct support from Changhua’s team for customization and after-sales service.

How to Buy

Browse the product catalog, request a quote, and place an order online. Changhua offers global shipping and technical support.

Through Online Marketplaces

Platforms

Alibaba

Benefits

Convenient for international buyers. Verified supplier profiles with customer reviews. Flexible payment methods, including bank transfers and online payments.

Example

On Alibaba, you can find Changhua's computerized flat knitting machines with detailed descriptions and minimum order quantities.

Industry Trade Shows and Exhibitions

Events

Changhua frequently participates in textile machinery trade shows, such as ITMA and Texworld.

Benefits

Hands-on experience with Changhua's machines. Networking with industry experts. Exclusive discounts and promotions.

How to Attend

Check Changhua's website for upcoming event schedules.

Benefits of Choosing Changhua Knitting Machines

Advanced Technology

Changhua's machines feature digital controls, high-speed rollers, and dynamic stitch capabilities for precise, high-quality output.

Versatility

From sweaters to shoe uppers, Changhua’s machines support a wide range of applications, making them ideal for diverse industries.

Durability

Built with high-quality materials, Changhua machines are designed for long-term use with minimal maintenance.

Customization

Changhua offers tailored solutions to meet specific production needs, including custom patterns and machine configurations.

Sustainability

Their Whole Garment machines reduce waste by producing seamless knitwear, supporting eco-friendly manufacturing.

Global Support

With a worldwide network of distributors and technical support teams, Changhua ensures prompt assistance wherever you are.

Conclusion

When searching for “where to buy a knitting machine,” Changhua Smart Manufacturing Technology Co., Ltd. stands out as the premier choice. With over 20 years of experience, a diverse range of computerized flat knitting machines, and a commitment to innovation, Changhua delivers solutions that meet the needs of designers, manufacturers, and businesses worldwide. Our machines offer unmatched precision, versatility, and sustainability, making them ideal for producing everything from fashion garments to technical textiles.

Contact us to request a quote, schedule a demo, or explore our full range of products.

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

ភាសាខ្មែរ

Bahasa Melayu

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

қазақ

Српски

हिन्दी

Kiswahili

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

עברית

اردو

Shqip

বাংলা

Hrvatski

Gaeilge

Māori

සිංහල

नेपाली

Oʻzbekcha

Aymara

Azərbaycan dili

Беларуская мова

Български

guarani

Lietuvių

Runasimi

Türkmençe