The Successful Showcase at The Bangladesh Expo: Changhua Knitting Machine Manufacturer Introduces Knitting Machinery

Changshu Changhua Smart Manufacturing Technology Co., Ltd., a leading innovator in the textile machinery industry, has been at the forefront of developing cutting-edge technology for over two decades. Specializing in the design, manufacture, and distribution of advanced knitting machines, we have established a strong global presence, catering to the needs of textile manufacturers worldwide. Our commitment to quality, innovation, and customer satisfaction has earned us a reputation as a trusted partner in the industry.

Recently, our company participated in the famous Bangladesh Expo, held in Dhaka. This event is renowned for attracting global leaders in the textile and apparel industry, providing us with an excellent platform to showcase the latest developments in knitting technology. Our participation not only strengthens our commitment to the Bangladeshi market, but also enables us to engage with industry professionals, share insights, and explore new business opportunities.

Company Overview

With a strong emphasis on research and development, we have consistently delivered high-quality, reliable, and efficient machinery that meets the evolving needs of the global textile industry. Our product portfolio includes a wide range of knitting machines, from flat knitting machines to embroidery machine, catering to various segments of the textile market.  Changhua Flat Knitting Machines.pdf

Changhua Flat Knitting Machines.pdf

Our mission is to empower textile manufacturers with state-of-the-art technology that enhances productivity, reduces operational costs, and minimizes environmental impact. Over the years, we have built a reputation for excellence, earning the trust of clients in over 30 countries. Our commitment to sustainability and innovation has positioned us as a preferred partner for textile manufacturers worldwide.

Workshop

Flat Knitting Machines

Warehouse

Exhibited Products: Collar Knitting Machines and Glove Knitting Machines

At the Bangladesh Expo, we showcased our two flagship products: the 68 Inch Double System Collar Knitting Machine and the 13G Glove Knitting Machine. Both machines are designed to deliver exceptional performance, efficiency, and versatility, making them ideal for the Bangladeshi textile industry.

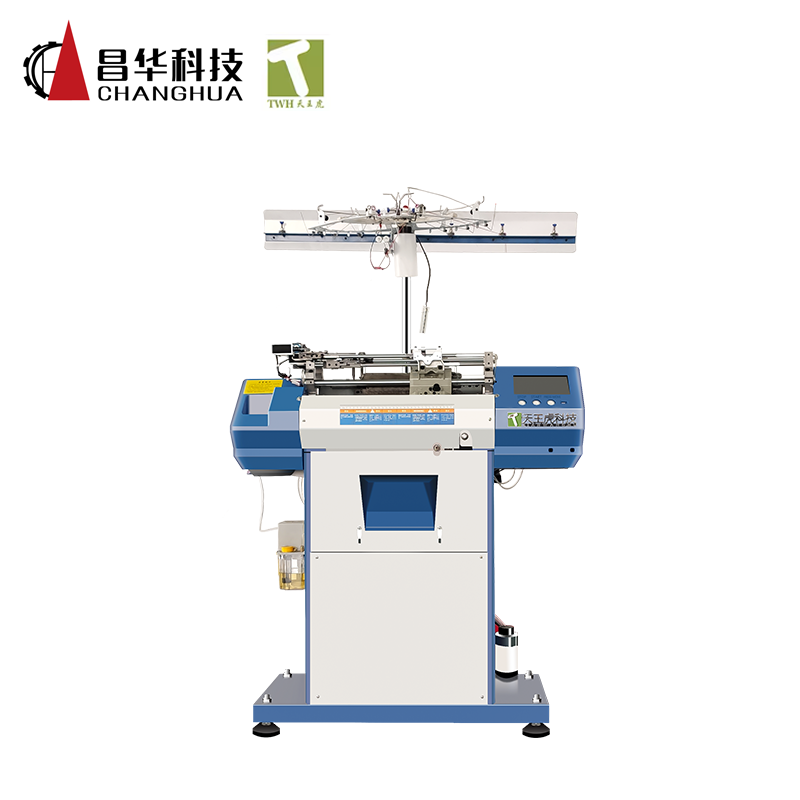

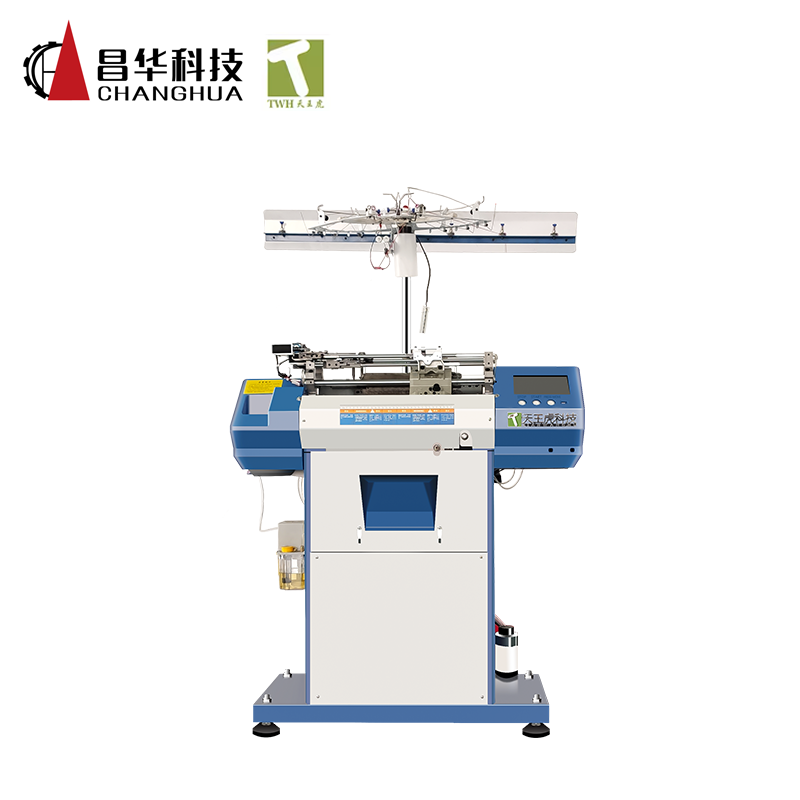

1. Collar Knitting Machine

The collar knitting machine is specially designed for the knitting of collars and ribs, Changhua Knitting Machine Manufacturer offer 4 different stitch patterns and 8 different sizes of the collar knitting machine. It’s an ideal machine for knitting collar, rib, apparent or hide shaping and even for other regular or irregular patterns. Its ability to produce high-quality collars at a rapid pace (max speed reach 1.6m/s) makes it an indispensable tool for apparel manufacturers looking to stay competitive in the fast-paced fashion industry.

Collar Knitting Machine

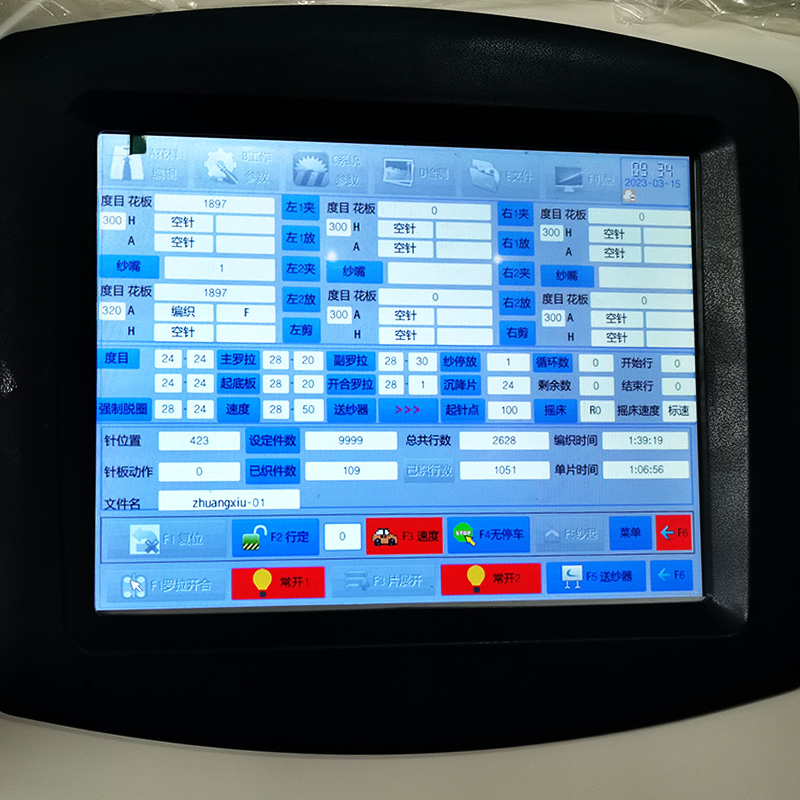

LCD Display

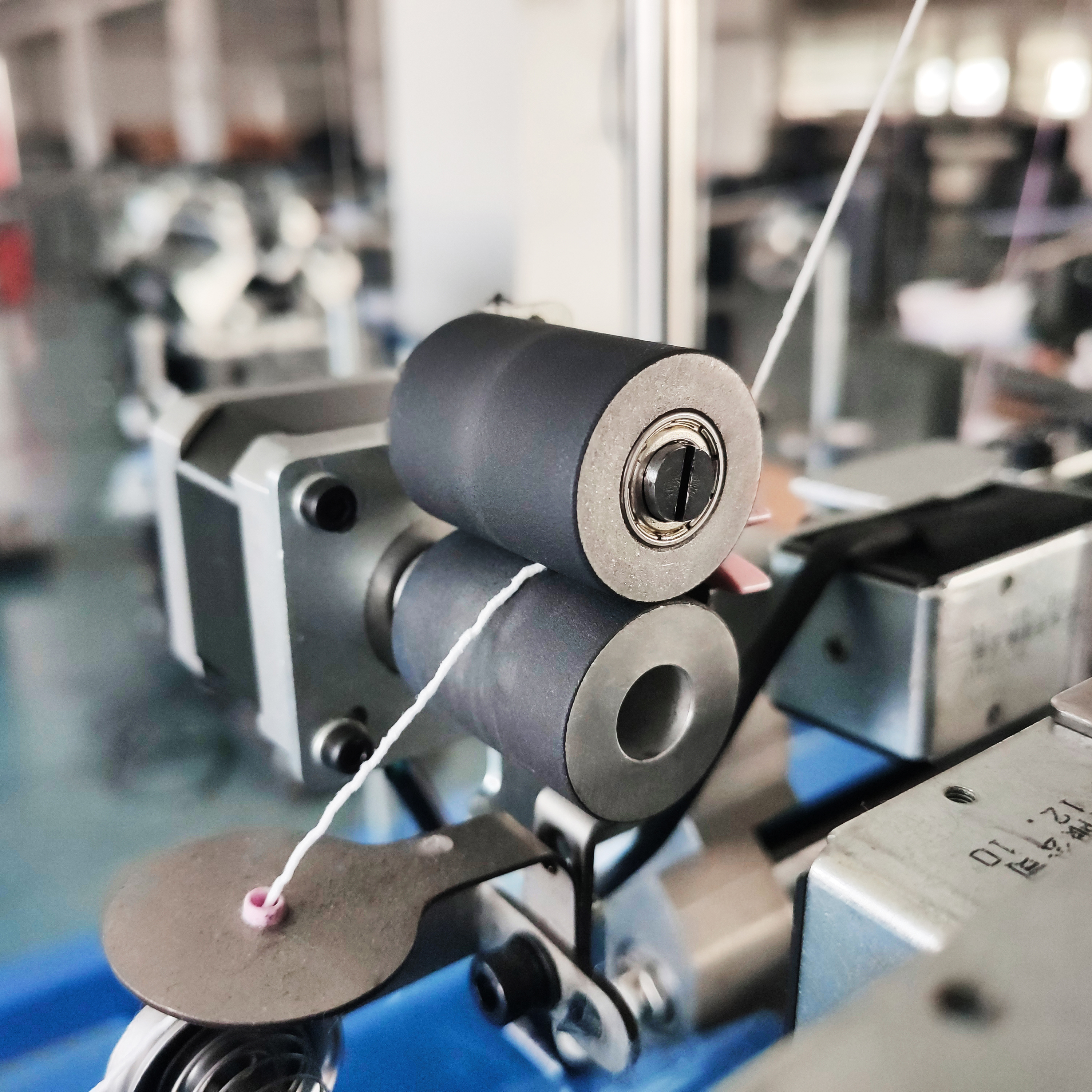

Machine Detail

Machine Detail

Key Features:

1. Efficient and accurate: Support double slide system, maximum speed: 1.6m/s, can ensure fast production and stitch density control.

2. Versatility : It can be applied to complex designs.

3. User-friendly : LCD display, multi-language support, simplified operation.

5. Automation : Automatic yarn feeding, color change and tension control reduce manual labor.

6. Durability : Made of high-quality materials, with long-term reliability.

7. Intelligent functions & Energy saving : Network connection for remote monitoring and ERP integration, low power consumption.

Gauge | 12G、14G、16、18G |

Knitting width | 36, 42, 52, 60, 68, 80,100, 120 Inch |

Knitting system | Single system, Double carriage single system (optional) |

Knitting speed | Controlled by servo-motor with 32 sections optional, max speed reach 1.6m/s |

Knitting function | Knit, miss, tuck, transfer, pointel, intarsia, jacquard, apparent or hide shaping and other regular or irregular patterns. |

Racking | Controlled by servo-motor racking within 2 inches and with fine adjusting function. |

Stitch density | Controlled by stepping motor, 32 section stitch select-able adjustable scope supported by subdivision technology: 0-650, the stitch of the knitwear can be accurately controlled. |

Dynamic stitch | Using high speed stepping motor, multi-stitch function can be achieved in one line. |

Needle selection | Advanced encoder reading pin.8-stage selecting needle setup composed of special electromagnet is regarded as efficient full width jacquard needle selector, which can be installed or removed simply from the carriage and maintained easily. |

Transfer system | Not affected by the direction of the carriage, minute knitting. |

Quickly turning | Intelligent switching braiding system improves machine weaving efficiency. |

Take-down system | Machine With high roller and sub roller, infrared alarm, computer programs instruction, stepper motor control, 32-stagetension selection with an adjustable range between 0-100. |

Color-changing system | 2x8 yarn feeders on each side of 3 guide rails, shift able on any needle position. |

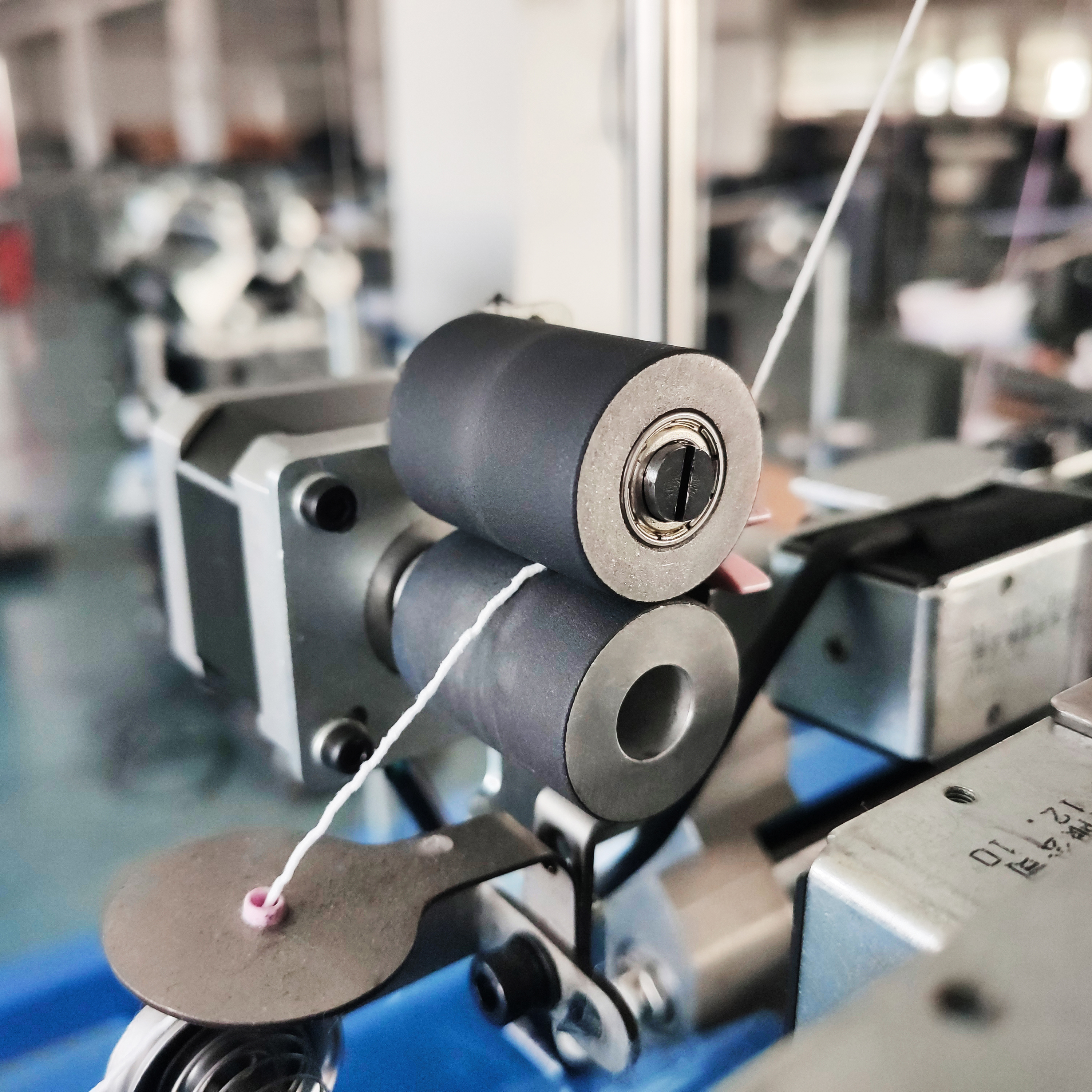

Yarn feeder device | Accurately control the tension of the yarn and ensure the consistency of the whole woven piece quality. |

Protection system | The machine will automatically alarm if yarn-breaking, knots, floating yarn, rewind, end of knitting, fail of racking, needle breakage, error programming occur, also set up the safety auto-lock protect device. |

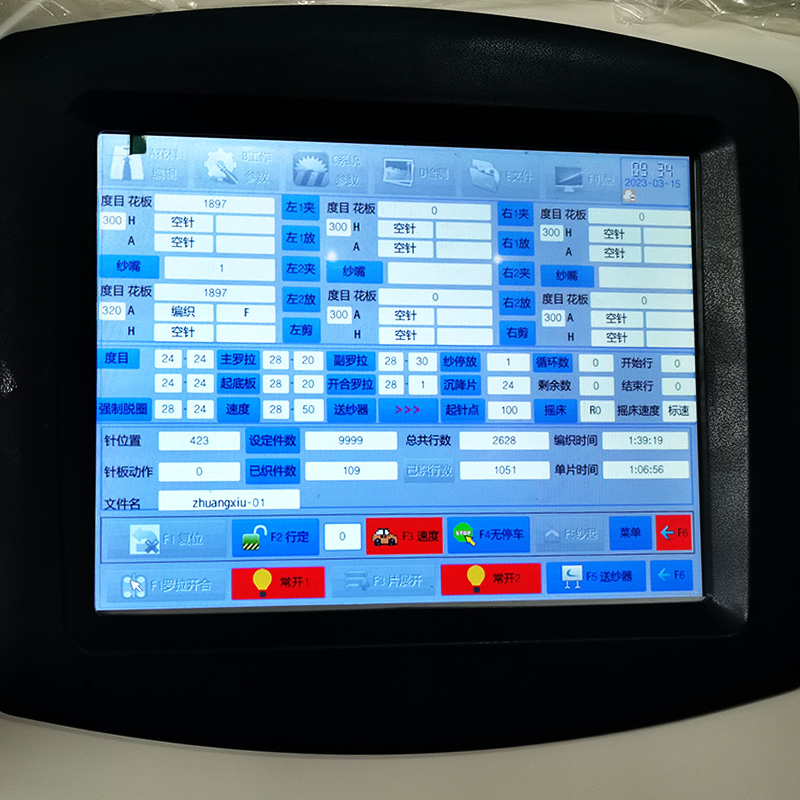

Control system | 1. LCD industrial display, can display various parameters, which can be adjustable during operation. 2.USB memory interface, System memory 2G. 3.Free design system is visual and easy to understand and software upgrade free of charge. 4.Support multi-language operation as Chinese and English, Spanish, Russian etc. |

Network function | Has network interface, enable remote-monitoring via network, and connecting with ERP system. |

Power supply | Single-phase 220V/three-phase 380V, adopt advanced CMOS technology, having memorizing function at power shock stop. |

Volume and weight | 2500*900*1700mm,700kgs(52inch) 3800*900*1700mm,950kgs(80inch double carriages) |

2. Glove Knitting Machine

Glove knitting machine is a new type of labor series model developed by the company at present, and is another outstanding product that attracted wide attention at the expo. Our company supports 7G, 10G and 13G configurations for a wide range of glove types and thicknesses.

Glove Knitting Machine

Machine Detail

Application

Key Features:

Wide range of applications: suitable for manufacturers in the medical, industrial and fashion industries

High Efficiency: Produces 240-350 pairs of gloves per day, depending on the gauge.

Advanced Control System: Features a 7-inch touch-screen display, electronic programming, and USB data transfer for easy operation and customization, even can achieve seamless production.

Energy Efficient: Reducing operational costs (only 200W).

Easy Maintenance: Automatic lubrication system ensures smooth operation and reduces downtime.

| Gauge | 7G/10G/13G |

| Power | 600W |

| Voltage | 220V 50-60HZ |

| Average Output | 350/330/240 Pairs |

| Consumption | 200W |

| Machine Table | 50/A Person |

Lubrication

| Automatic lubrication |

| Stitch Density | Step motor controller |

| Control System | Computer control, Electronic programming, 7-inch touch-screen display and USB data transfer |

| Drive System | Double belt drive, AC servo motor |

| Carriage | Super compact & light weight carriage |

| Automatic Overlock | YES |

| Net Weight | 170KGS |

| Gross Weight | 200KGS |

| Machine Size | 1050*570*1700mm(L*M*H) |

| Wood Size | 1220*700*1500mm(L*M*H) |

| Container Capacity | 48 sets/ 20'FT 96 sets/ 40'HQ |

Why Choose Changhua Knitting Machine Manufacturer for Your Knitting Machinery Needs?

Our commitment to innovation, quality, and customer satisfaction has earned us a reputation as a leader in the industry. Here are some reasons why you should choose us for your knitting machinery needs:

1. Cutting-Edge Technology: Our machines are equipped with the latest technology, ensuring high performance, efficiency, and reliability.

2. Custom Solutions: We understand that every manufacturer has unique needs. That's why we offer customizable solutions tailored to your specific requirements.

3. Global Support: We provide comprehensive support and after-sales service to ensure your machines operate at peak performance.

4. Sustainability: We are committed to reducing the environmental impact of textile manufacturing. Our machines are designed with energy-saving features and eco-friendly materials.

5. Proven Track Record: With over 20 years of experience, we have a proven track record of delivering high-quality machinery that meets the needs of our clients.

Post-Expo Reflections: A Resounding Success

Participating in the Bangladesh Expo was an incredibly rewarding experience for Changhua Knitting Machine Manufacturer. The event provided us with a unique opportunity to connect with industry leaders, showcase our latest innovations, and gain valuable insights into the evolving needs of the textile market.

The most significant takeaways from the expo was the overwhelming interest in our Collar Knitting Machine and Glove Knitting Machine. The positive feedback we received from attendees reaffirmed our belief in the potential of these products to revolutionize the textile industry. Many visitors were impressed by the machines' advanced features, efficiency, and versatility, and we are confident that these products will play a crucial role in shaping the future of knitting technology.

Final Thoughts

The Bangladesh Expo was a testament to the vibrancy and dynamism of the global textile industry. It was an honor to be part of such a prestigious event and to contribute to the ongoing evolution of the industry. We are grateful for the opportunity to connect with so many talented professionals and to share our passion for innovation and excellence.

As we reflect on our experience at the expo, we are filled with a sense of optimism and excitement for the future. The textile industry is undergoing a period of rapid transformation, and we are proud to be at the forefront of this change. With our cutting-edge technology, unwavering commitment to quality, and dedication to sustainability, we are confident that our company continue to lead the way in the textile machinery industry.

We would like to extend our heartfelt thanks to all the attendees, organizers, and partners who made the Bangladesh Expo such a memorable and successful event. We look forward to continuing our journey of innovation and collaboration, and we are excited about the opportunities that lie ahead. Together, we can shape the future of the textile industry and create a more sustainable, efficient, and prosperous world.

Conclusion

In summary, Changshu Changhua Smart Manufacturing Technology Co., Ltd.'s participation in the Bangladesh Expo was a resounding success. We were able to showcase our latest innovations, including the Collar Knitting Machine and Glove Knitting Machine, and engage with industry professionals from around the world. The positive feedback and interest we received reaffirm our commitment to delivering high-quality, efficient, and sustainable knitting machinery.

As we move forward, we remain dedicated to pushing the boundaries of innovation and providing our clients with the tools they need to succeed in an ever-changing industry. We are excited about the future and look forward to continuing our journey of growth, collaboration, and excellence in the textile machinery industry.

Thank you to everyone who visited our booth and supported us at the Bangladesh Expo. We are grateful for the opportunity to connect with you and look forward to building lasting partnerships that will drive the future of the textile industry. Together, we can achieve great things and create a brighter, more sustainable future for all.

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

ភាសាខ្មែរ

Bahasa Melayu

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

қазақ

Српски

हिन्दी

Kiswahili

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

עברית

اردو

Shqip

বাংলা

Hrvatski

Gaeilge

Māori

සිංහල

नेपाली

Oʻzbekcha

Aymara

Azərbaycan dili

Беларуская мова

Български

guarani

Lietuvių

Runasimi

Türkmençe

Machine Detail

Machine Detail