Computerized Flat Knitting Machine Starting Method

In order to prevent the bottom edge of the garment piece from falling apart and for pulling, the fabric should firstly be knitted with a row of starting loops, and the hanging arc of the first row is called starting row, which is generally carried out in the form of 1+1 ribbing. After the mouth in order to make the edge of the fabric clean, full, and the bottom edge of the garment piece of the hem has a front to the reverse side of the tendency to curl, should be knitted one to three rows of cylindrical weft flat knitting coils, commonly known as playing the idle, the general fabric front of the idle column than the reverse side of the idle column more than the number of a column, the conventional idle columns of the number of ratio of 2:1, 3:2. (Machine head from left to right or right to left knitting row of coils called a row of horizontal columns) mouth, the operation of idle can be performed in accordance with the following steps: (the head from left to right or right to left) The following steps can be performed.

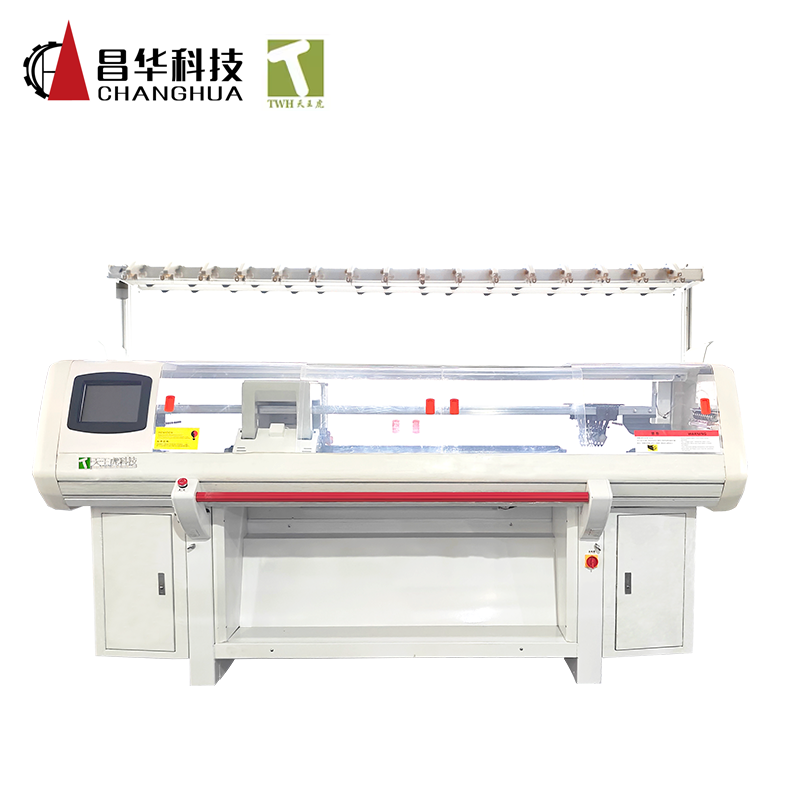

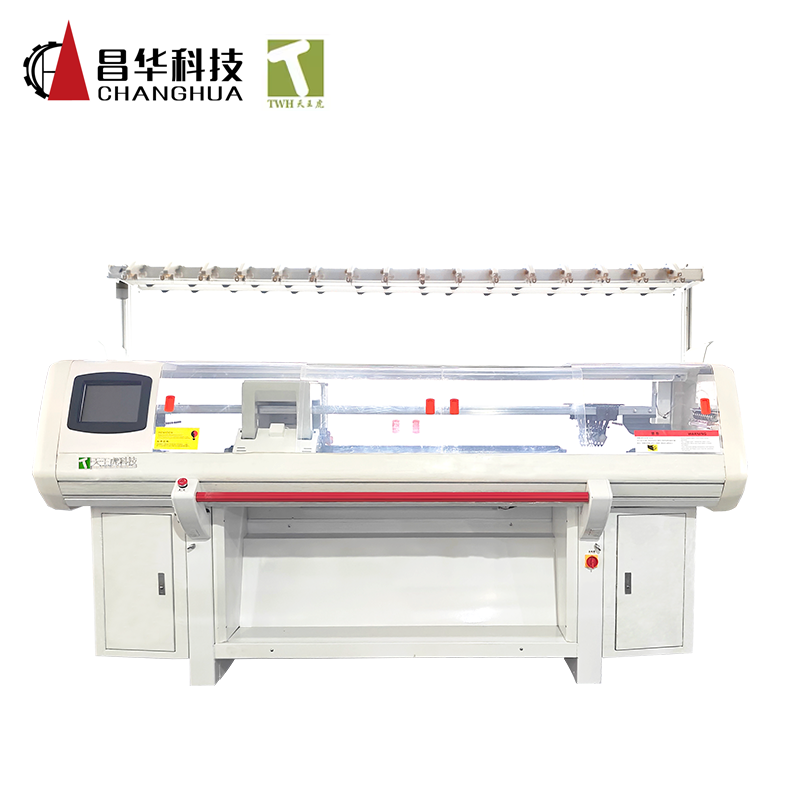

Computerized Flat Knitting Machine

GE Computerized Scarf Flat Knitting Machine

(1) After the rib knitting operation, slowly push the machine head to run 1-2 traverse rows of empty needles without yarn, so that all working needles enter the needleway, and the needle tongues are opened by brushes for yarn feeding.

(2) The machine head drives the yarn guide with wool yarn through the yarn guide converter, threads the wool yarn into the needle bed gap opening, and after the yarn head loop is fixed, pushes the machine head to knit up the opening cross train, and the machine head stops on the left side.

(3) Check whether there is any needle with missing yarn, if there is, make up for it, then pinch the comb pectinate with the left hand (commonly known as stringing board), extract the steel wire in the comb pectinate, and put the silk buckle on the comb pectinate from the gap opening of the front and rear needle beds by the lower part of the machine seat from the bottom upward symmetrically from left to right through the start of the cross rows, so that the silk mouth is exposed to the outside of the gap opening of the needle bed, and then the right hand will be threaded through the steel wire into the silk mouth eyelets.

(4) Hang a heavy hammer under the fixed width comb, at this time, the hammer should be lighter, so as to avoid the latter sequence of knitting wool yarn breakage.

(5) Close the No. 1 and No. 3 needle triangle, according to the fabric process requirements for “idle” knitting, such as process requirements are 2:1, then push the head of the three horizontal columns, the head stops on the right.

(6) Such as knitting 2 + 2 rib, should be board moving needle bed shift handle, before and after the needle bed stitch arrangement can not make the neighboring two needles at the same time heavy set of a coil, starting mouth, idle operation with 1 + 1 rib.

(7) After starting and idling 1+1 (2+2) rib, open the No. 1 and No. 3 needle triangle, adjust the triangle density, you can start knitting ribbed blanks. If you want to knit the weft flat knitting organization, then turn the loop on the knitting needle of the front needle bed to the empty needle of the back needle bed, and continue knitting.

(8) If you want to get off the machine after knitting the appropriate length, first break the yarn, put down the hammer, and then hold up the string plate with your left hand, and shake the machine head with your right hand.

Knitting Ribbing

Ribbing operation Most of the cardigan pieces are made with a more elastic ribbed tissue for the hem and cuffs, so the starting row of stitches is in the form of ribbing. The commonly used starting rib is 1+1 rib and 2+2 rib.

Triangle density adjustment.

Rib scraper with no teeth mouth side, the needle according to the fabric width requirements pushed to the location of the work area, according to the requirements of the fabric tightness, push the machine head in the case of the empty needle, one by one to send open into the circle triangle on the Yuanbao nut for adjustment, so that the needle through the triangle by pressing the needle needle after the needle in the bed of the barrel at the mouth of the position of the left and right, before and after the bending depth of the yarn to maintain consistency, the use of the limit of pressure will be adjusted to become a triangle of the circle limit, the limit of pressure plate according to fabric technology requirements, the upper and lower limit of The upper and lower limit plates are set according to the fabric process requirements.

For example, 1 +1 rib general 2 No. 3 into the circle triangle using the upper density limit, No. 1 No. 4 into the circle triangle using the lower density limit, as well as, four flat organization are generally used in the lower density limit. Limit, but also the use of different thicknesses of paper cut into a T-shaped pad into the limit between the pressure plate and the score needle for tightening and fine-tuning. Density adjustment of the correct or not, will directly affect the quality of the fabric blank.

1+1 ribbing operation steps.

(a) stop the right side of the machine head, with 1 +1 ribbing scraper with teeth side, according to the fabric width requirements of a needle every other needle will be used to push the needle to the working position.

(b) Trigger the needle bed shift handle, so that the front and back of the needle bed grooves relative to the knitting needle cross arrangement.

(3) 2+2 Ribbing Procedure.

(a) 2 + 2 ribbing scraper with the mouth of the teeth, the same operation process and 1 + 1 ribbing, the needle starting arrangement does not make the adjacent two needles at the same time to re-set a coil, at this time, the needle bed groove and needles are cross-arrangement, and before and after the needle bed of the neighboring arrangement of the two needles between the two needle for a pitch.

(b) After starting the opening, use the needle bed crank to swing the needle window to the correct position of the 2+2 rib row.

Loop shifting operation method

Loop shifting operation method can be divided into turning the needle, closing the needle, release the needle, loop exchange (twisted flower) and other operations.

(1) turning the needle: used for weft flat knitting needle in the knitting 1 +1 rib after an operation process, the operation process is as follows: (a) first open and loose after the needle bed No. 2, the operation process is as follows.

(a) first loosen the back of the needle bed No. 2 into the loop triangle (at this time the machine stops the right side), knitting a horizontal column, so that the back of the needle bed coil enlargement.

(b) Push up the empty needle on the rear needle bed into the working area and open the needle tongue.

(c) Using the needle flap, transfer all the loops from the front needle bed to the empty needles on the rear needle bed.

(d) the back of the needle bed working needle heel scraping, the front needle bed needle all back to the non-working position, the loose No. 2 into the circle triangle to return to the original position, adjust the density, you can continue to knit weft flat knitted fabrics, in order to ensure that the edge of the coil smoothly into the circle and the fabric is tight and uniform, it is desirable to hang a small hammer in the two edges, along with the lengthening of the fabric, should be timely to shift the small hammer, to ensure that the edge of the certain tensile force.

(2) Needle closing.

Needle collection process is to reduce the number of working needles in the horizontal machine knitting (width) of a method, that is, the most edge of a working needle coil transfer to an adjacent working needle, so that the needle on the existence of two coils, the tool is the needle collector, also known as the removal of the loop needle, 1, 2, 3 needles, and other specifications, according to the fabric process for selection. After receiving the needle must be returned to the empty needle does not work position, so as to avoid the empty needle to re-enter the work state, and even the occurrence of needle collision, receiving the needle coil of the working needle should be scraped with other working needles before continuing to knit.

(3) Needle Release.

Needle release process is a method to increase the number of working needles (width) in flat knitting machine, the operation process.

Stop the machine head on the side of the need to release the needle, push on the most edge of the empty needle, open the needle tongue.

After knitting a horizontal row, the empty needle pad into the wool yarn, hanging on the hanging small weight, continue to knit after the sequence.

Note on needle release.

When knitting the weft flat knitting organization, release the needle can only be carried out needle by needle.

When both sides need to release the needle at the same time, in the machine after the head shake out of the width, should be the first to put the head side of the empty needle, and then the machine will shake a horizontal column, to the other side, and then put the side of the empty needle, not at the same time on both sides together, not to mention when the head stops in the width of the heavy needle release.

When a time to put more than one needle, should be equipped with the appropriate pulling mechanism.

Caveat

(1) When hand cranking the machine head, the person should stand firmly, the force should be even and moderate, and the direction of force should be the same as the direction of machine head sliding.

(2) When knitting, the machine head can not be adjusted in the knitting area, the machine head must be pushed through the most edge of the working needle more than 2cm to adjust the direction, so as not to damage the machine parts and fabric.

(3) The machine head is in the knitting area, can not trigger the needle bed shift wrench, otherwise it will seriously damage the needle, and can not toggle all kinds of triangular adjusting devices and switches, so as to avoid the occurrence of needle accident, damage to the machine parts.

(4)When releasing the needle, the needle should be pushed to be flush with the working needle; after collecting the needle or copying the needle, the empty needle should be retreated to the non-working position, do not stay in the position between the needle stopping area and the working area, otherwise it will cause the needle collision.

(5)When the needle collision occurs, the starting triangle should be closed, and then the head of the machine out of the knitting area, do not pull the needle hook by hand to avoid damage to the fingers.

(6) When the fabric width is too large, the head movement increases, so that the head of the excess yarn, it is appropriate to use your fingers to take a little bit of the excess yarn, with the picking spring will be the excess yarn back, to avoid causing the edge of the coil relaxation or even produce a “pigtail” and exclusion of the edge.

(7) When dropping the piece, you must first remove the pulling weight to prevent the weight from falling to the ground and hurting your feet.

Knitting machine applications

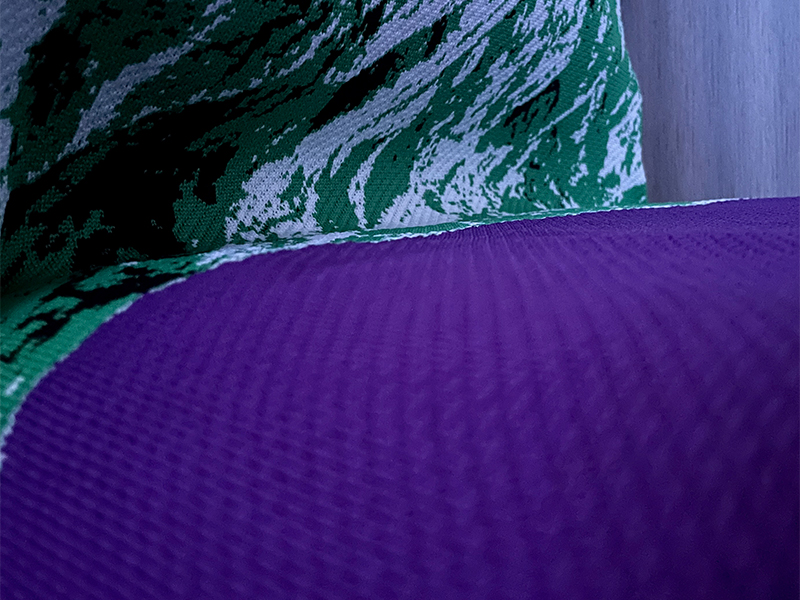

The machine is suitable for wool, rabbit hair, camel hair, cashmere, silk and man-made synthetic fibers, blended yarns, etc. Knitting single and double-sided plain, ribbed, inter-colored, pitched strips, twisted rope, bead ground, three flat, four flat, pulling wave, moving the needle, valley wave, shoveling chickens, moving the needle to pick the holes, as well as the second and third level of knitting and other fancy wool sweater, cashmere sweater, cashmere pants, scarves, hats, and other types of knitted products. Widely used in family, wool sweater store, wool sweater factory, scarf hat enterprise, clothing and apparel enterprise knitting.

Knitting machine selection

(1) the choice of needle type: the higher the needle type, such as 12 needles, suitable for processing the finer wool, the thinner the fabric produced; the lower the needle type, such as 3 needles, suitable for processing the thicker wool, the thicker the fabric produced. Such as 6 needles, the wool suitable for processing moderate, the fabric produced by moderate. So the purchase should be considered from two aspects: First, the thickness of the wool processing. Selection of wool thicker, then select the knitting machine should be the lower the needle type; selection of wool finer, then select the knitting machine should be the higher the needle type; Second, the production of product varieties. If the production of spring and summer to take the thin and light type of clothing, you should choose a higher needle type of knitting machine; if the production of winter to take the thick type of clothing, you should choose a lower needle type of knitting machine.

(2) the choice of needle width: the width of the needle width will directly limit the maximum width of the knitted piece of clothing. The wider the needle width, such as 40 or 42 inches, the maximum size of the piece of clothing can be produced on the wider; the narrower the needle width, such as 36 inches, the maximum width of the piece of clothing can be produced on the narrower. So according to the production of product styles and garment specifications, or to produce products according to the clothing piece of the maximum number of longitudinal rows of transverse process to select the width of the needle. That is, according to the product specifications, fabric density, calculate the maximum width of the clothing piece part of the number of knitting needles, and then according to the needle type to determine the width of the needle. Generally speaking: the larger the finished product specifications, the wider the required needle width, and vice versa.

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

ភាសាខ្មែរ

Bahasa Melayu

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

қазақ

Српски

हिन्दी

Kiswahili

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

עברית

اردو

Shqip

বাংলা

Hrvatski

Gaeilge

Māori

සිංහල

नेपाली

Oʻzbekcha

Aymara

Azərbaycan dili

Беларуская мова

Български

guarani

Lietuvių

Runasimi

Türkmençe