The 2025 Knitting Machinery Expo in Dhaka was a landmark event for the global textile and knitting industry, bringing together innovators, manufacturers, and industry leaders under one roof. Changhua Knitting Machine Manufacturer was proud to participate in this prestigious event, showcasing our latest advancements in collar knitting machines and glove knitting machines. The expo provided an excellent platform to connect with industry professionals, demonstrate our innovative solutions, and reinforce our position as a leader in knitting technology. This article provides a comprehensive recap of our experience at the expo, including an overview of our company, a detailed look at our showcased products, and the impact of our participation.

Company Overview: Changhua Knitting Machine Manufacturer – Pioneers in Knitting Technology

Changhua has been at the forefront of the knitting machinery industry for over 20 years. With a mission to revolutionize textile production, we have consistently delivered state-of-the-art knitting machines that combine precision, efficiency, and sustainability. Our commitment to innovation and customer satisfaction has made us a trusted partner for businesses across the fashion, automotive, home furnishings, and sportswear industries. Headquartered in Jiangsu, China, we operate globally, serving clients in over South Africa countries. Our team of engineers and designers is dedicated to pushing the boundaries of knitting technology, ensuring that our machines meet the evolving demands of modern manufacturing. At the 2025 Knitting Machinery Expo in Dhaka, we reaffirmed our commitment to excellence by showcasing our latest innovations in collar and glove knitting machines. This is the one-stop product catalog of  Changhua one-stop programmes.pdf and the product catalog of

Changhua one-stop programmes.pdf and the product catalog of  Changhua Flat Knitting Machine.pdf.

Changhua Flat Knitting Machine.pdf.

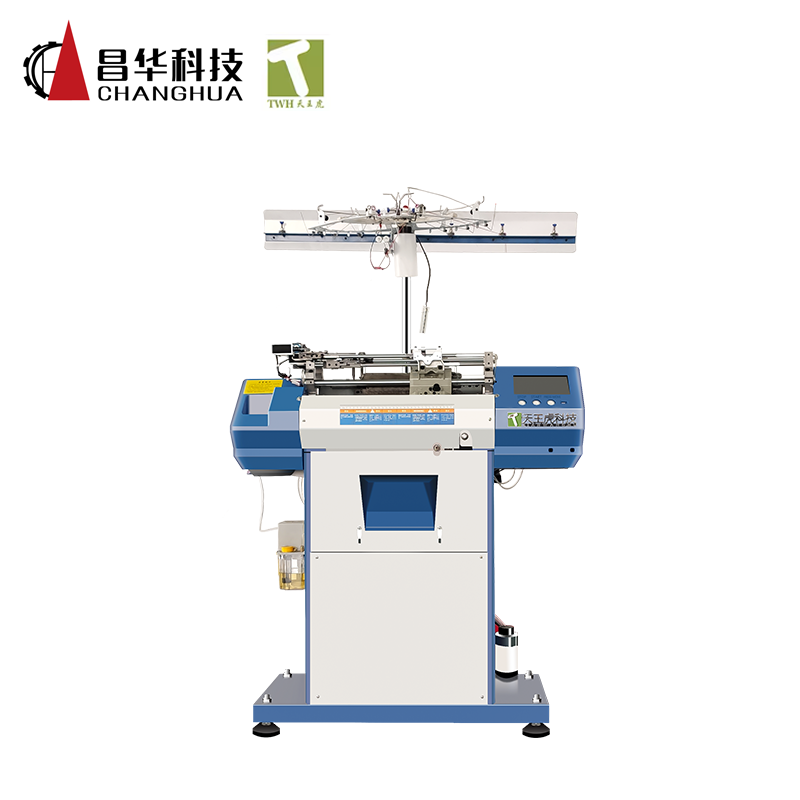

Product Showcase: Collar Knitting Machines

Our collar knitting machines were one of the highlights of the expo, drawing significant attention from attendees. Designed to meet the needs of high-end fashion and functional apparel manufacturers, these machines offer unmatched precision, speed, and versatility.

This is the product parameter of collar making machine.

Gauge | 12G、14G、16、18G |

Knitting width | 36, 42, 52, 60, 68, 80,100, 120 Inch |

Knitting system | Single system, Double carriage single system (optional) |

Knitting speed | Controlled by servo-motor with 32 sections optional, max speed reach 1.6m/s |

Knitting function | Knit, miss, tuck, transfer, pointel, intarsia, jacquard, apparent or hide shaping and other regular or irregular patterns. |

Racking | Controlled by servo-motor racking within 2 inches and with fine adjusting function. |

Stitch density | Controlled by stepping motor, 32 section stitch select-able adjustable scope supported by subdivision technology: 0-650, the stitch of the knitwear can be accurately controlled. |

Dynamic stitch | Using high speed stepping motor, multi-stitch function can be achieved in one line. |

Needle selection | Advanced encoder reading pin.8-stage selecting needle setup composed of special electromagnet is regarded as efficient full width jacquard needle selector, which can be installed or removed simply from the carriage and maintained easily. |

Transfer system | Not affected by the direction of the carriage, minute knitting. |

Quickly turning | Intelligent switching braiding system improves machine weaving efficiency. |

Take-down system | Machine With high roller and sub roller, infrared alarm, computer programs instruction, stepper motor control, 32-stagetension selection with an adjustable range between 0-100. |

Color-changing system | 2x8 yarn feeders on each side of 3 guide rails, shift able on any needle position. |

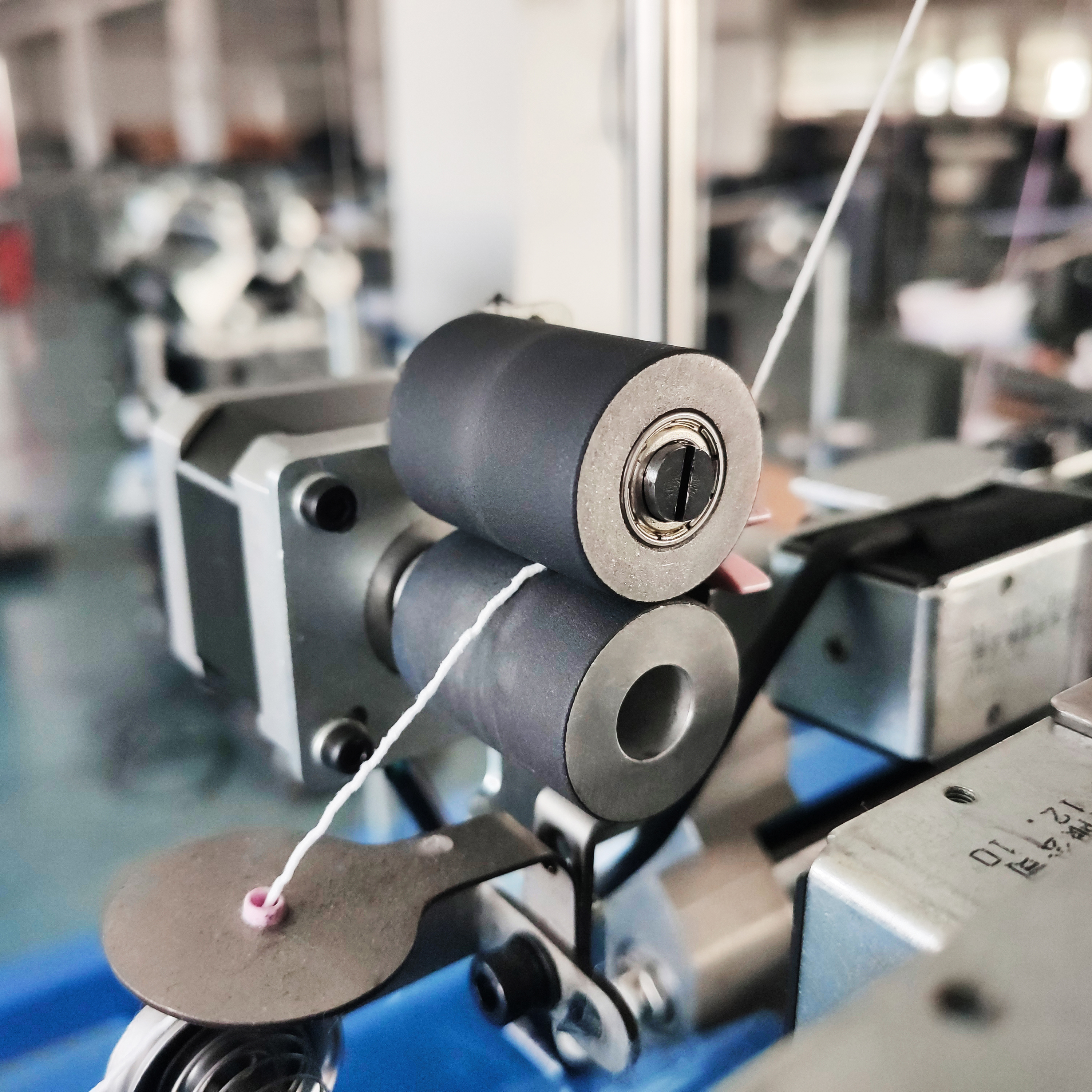

Yarn feeder device | Accurately control the tension of the yarn and ensure the consistency of the whole woven piece quality. |

Protection system | The machine will automatically alarm if yarn-breaking, knots, floating yarn, rewind, end of knitting, fail of racking, needle breakage, error programming occur, also set up the safety auto-lock protect device. |

Control system | 1. LCD industrial display, can display various parameters, which can be adjustable during operation. 2.USB memory interface, System memory 2G. 3.Free design system is visual and easy to understand and software upgrade free of charge. 4.Support multi-language operation as Chinese and English, Spanish, Russian etc. |

Network function | Has network interface, enable remote-monitoring via network, and connecting with ERP system. |

Power supply | Single-phase 220V/three-phase 380V, adopt advanced CMOS technology, having memorizing function at power shock stop. |

Volume and weight | 2500*900*1700mm,700kgs(52inch) 3800*900*1700mm,950kgs(80inch double carriages) |

1. Precision and Customization

Our collar knitting machines are engineered to produce flawless collars with intricate designs and perfect finishes. The machines feature advanced tension control systems and customizable stitch patterns, allowing manufacturers to create collars that meet specific design requirements. Whether it’s a delicate lace collar for a luxury garment or a sturdy ribbed collar for workwear, our machines deliver consistent, high-quality results.

2. High-Speed Production

In today’s fast-paced market, efficiency is key. Our collar knitting machines are designed to maximize productivity without compromising on quality. With high-speed knitting capabilities and automated yarn feeding systems, manufacturers can significantly reduce production times and meet tight deadlines. This feature was particularly appealing to attendees from the fast-fashion sector, who are constantly under pressure to deliver new designs quickly.

3. Versatility Across Materials

One of the standout features of our collar knitting machines is their ability to handle a wide range of materials, from fine silk and cotton to high-performance synthetic fibers. This versatility makes our machines ideal for manufacturers producing diverse product lines. At the expo, we demonstrated how our machines can seamlessly switch between materials, showcasing their adaptability and ease of use.

Collar Knitting Machine

Semi-auto Knitting Machine

Product Showcase: Glove Knitting Machines

Our glove knitting machines were another major attraction at the expo. Designed to meet the growing demand for high-quality, precision-knit gloves, these machines offer advanced features that cater to various industries, including medical, automotive, and sportswear.

| Gauge | 7G/10G/13G |

| Power | 600W |

| Voltage | 220V 50-60HZ |

| Average Output | 350/330/240 Pairs |

| Consumption | 200W |

| Machine Table | 50/A Person |

Lubrication

| Automatic lubrication |

| Stitch Density | Step motor controller |

| Control System | Computer control,Electronic programming, 7-inch touch-screen display and USB data transfer |

| Drive System | Double belt drive, AC servo motor |

| Carriage | Super compact & light weight carriage |

| Automatic Overlock | YES |

| Net Weight | 170KGS |

| Gross Weight | 200KGS |

| Machine Size | 1050*570*1700mm(L*M*H) |

| Wood Size | 1220*700*1500mm(L*M*H) |

| Container Capacity | 48 sets/ 20'FT 96 sets/ 40'HQ |

1. Superior Knitting Technology

Our glove knitting machines incorporate the latest advancements in knitting technology to produce gloves that are both comfortable and durable. With precise stitch control and seamless knitting capabilities, manufacturers can create gloves that offer a perfect fit and exceptional performance. At the expo, we demonstrated how our machines produce gloves with reinforced palms, touchscreen compatibility, and thermal insulation, catering to the specific needs of different industries.

2. Customization for Diverse Applications

Every industry has unique requirements when it comes to gloves, and our machines are designed to meet these diverse needs. Attendees were particularly impressed by the customization options available, which allow manufacturers to produce gloves with specific features such as anti-slip grips, cut-resistant materials, and breathable fabrics. This flexibility makes our glove knitting machines a valuable asset for businesses looking to expand their product offerings.

3. Sustainability and Energy Efficiency

Sustainability was a key theme at the 2025 Knitting Machinery Expo, and our glove knitting machines were designed with this in mind. Featuring energy-efficient motors and eco-friendly materials, our machines help manufacturers reduce their environmental impact while maintaining high production standards. This commitment to sustainability resonated strongly with attendees, many of whom are actively seeking ways to make their operations more environmentally friendly.

Glove Knitting Machine

Sock Knitting Machine

Highlights from the 2025 Knitting Machinery Expo in Dhaka

The 2025 Knitting Machinery Expo in Dhaka was a resounding success for Changhua Knitting Machine Manufacturer. Here are some of the key highlights from our participation:

1. Strong Visitor Engagement

Our booth attracted a steady stream of visitors throughout the expo, including manufacturers, designers, and industry experts. The live demonstrations of our collar and glove knitting machines were particularly popular, allowing attendees to see the machines in action and appreciate their capabilities firsthand. Many visitors expressed interest in our products, and we are currently following up with numerous leads generated during the event.

2. Networking Opportunities

The expo provided an excellent platform for networking with industry leaders and potential partners. We had the opportunity to connect with key players in the textile and knitting industries, exchange ideas, and explore potential collaborations. These interactions have opened up new avenues for growth and innovation for Changhua Knitting Machine Manufacturer.

3. Positive Feedback and Testimonials

The feedback we received from attendees was overwhelmingly positive. Many visitors praised the precision, speed, and versatility of our machines, as well as our commitment to sustainability. Several industry experts also commended our efforts to push the boundaries of knitting technology, reinforcing our reputation as a leader in the field.

4. Media Coverage and Brand Visibility

Our participation in the expo garnered significant media attention, with several industry publications featuring our products and innovations. This increased visibility has helped strengthen our brand presence in the global market and position Changhua Knitting Machine Manufacturer as a go-to provider of advanced knitting solutions.

The Impact of Our Participation

Our participation in the 2025 Knitting Machinery Expo in Dhaka has had a profound impact on our business. Here are some of the key outcomes:

1. Increased Market Reach

The expo provided us with a platform to showcase our products to a global audience, helping us expand our market reach. We connected with potential clients from Asia, Europe, and the Americas, many of whom expressed interest in our machines. This has opened up new opportunities for growth and expansion in key markets.

2. Enhanced Brand Reputation

By showcasing our latest innovations at the expo, we reinforced our reputation as a leader in knitting technology. The positive feedback and media coverage we received have further enhanced our brand image, making Changhua Knitting Machine Manufacturer a trusted name in the industry.

3. Valuable Insights

The expo also provided us with valuable insights into the latest trends and challenges in the knitting industry. By engaging with attendees and industry experts, we gained a deeper understanding of the needs and preferences of our target market. These insights will guide our future product development efforts, ensuring that we continue to deliver solutions that meet the evolving demands of our clients.

Looking Ahead: The Future of Knitting Technology

As we reflect on our success at the 2025 Knitting Machinery Expo in Dhaka, we are excited about the future of knitting technology. At Changhua Knitting Machine Manufacturer, we are committed to driving innovation and pushing the boundaries of what’s possible in textile production. Our participation in the expo has inspired us to continue developing cutting-edge solutions that combine precision, efficiency, and sustainability.

We are already working on new advancements in collar and glove knitting machines, with a focus on automation, smart technology, and eco-friendly production. We look forward to showcasing these innovations at future industry events and continuing to support our clients in achieving their business goals.

Changhua Flat Knitting Machines At 2025 Knitting Machinery Expo in Dhaka

The 2025 Knitting Machinery Expo in Dhaka was a resounding success for Changhua Knitting Machine Manufacturer. Our participation allowed us to showcase our latest innovations in collar and glove knitting machines, connect with industry leaders, and strengthen our brand presence in the global market. The positive feedback and strong engagement we received are a testament to the quality and versatility of our products.

As we look ahead, we are excited to build on the momentum generated at the expo and continue driving innovation in the knitting industry. We extend our gratitude to all the attendees, partners, and organizers who made this event a success and look forward to participating in future expos.

For more information about our products and solutions, visit our website or contact us . Together, let’s knit a brighter future.

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

ភាសាខ្មែរ

Bahasa Melayu

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

қазақ

Српски

हिन्दी

Kiswahili

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

עברית

اردو

Shqip

বাংলা

Hrvatski

Gaeilge

Māori

සිංහල

नेपाली

Oʻzbekcha

Aymara

Azərbaycan dili

Беларуская мова

Български

guarani

Lietuvių

Runasimi

Türkmençe